Polyethylene Terephthalate Plastic (PET) Information

What is Polyethylene Terephthalate or PET?

PET, or polyethylene terephthalate, is a type of plastic that is commonly used in the manufacturing of various products. It is a thermoplastic polymer that is created by polymerizing ethylene glycol and terephthalic acid, or by using dimethyl terephthalate and ethylene glycol. This results in a strong, durable material that has a number of desirable properties, making it a popular choice for a wide range of applications. (Source: britannica.com)

Uses of Polyethylene Terephthalate or PET

One of the most common uses of PET plastic is in the production of bottles, containers, and packaging for food and beverages. PET is preferred for these applications because it is lightweight, shatterproof, and can be easily molded into different shapes and sizes. PET plastic is also used in the textile industry to make fabrics and clothing, as well as in the construction industry to manufacture insulation materials. In addition, PET plastic is used in the production of various household items such as trays, straws, and toothbrushes. Its durability and resistance to heat and moisture make it a popular choice for these applications.

The Top 5 Uses of PET in the United States:

- Bottled water: commonly used to make water bottles. It is lightweight, durable, and shatterproof, making it ideal for packaging beverages.

- Food packaging: used to make packaging for a wide range of food products, including fruit, vegetables, baked goods, and meat. It is also used to make microwaveable food containers and trays.

- Textile fibers: can be processed into textile fibers, which are used to make clothing, carpets, and upholstery.

- Electronics: used to make electronic components, such as mobile phone cases, laptop casings, and computer keyboards.

- Medical equipment: used to make medical equipment, such as syringes, IV bags, and pill bottles.

Advantages of Polyethylene Terephthalate Plastic

One of the most notable properties of PET plastic is its strength and durability. It is a highly resilient material that is resistant to impact, and it can withstand a wide range of temperatures without becoming damaged. This makes it an ideal choice for products that need to be able to withstand harsh conditions, such as food packaging or water bottles.Another key advantage of PET plastic is its transparency. It is a highly clear material that is able to showcase the contents of a container, making it an ideal choice for products such as food and beverage packaging. PET plastic is also able to maintain its transparency over time, which helps to ensure that the product remains visually appealing to consumers.

In addition to its strength and transparency, PET plastic is also highly resistant to chemicals. This means that it can be used to store a wide range of substances without becoming damaged or contaminated. It is commonly used in the manufacturing of pharmaceutical packaging and laboratory equipment for this reason.

PET plastic is also highly versatile in terms of its processing capabilities. It can be easily molded into a variety of shapes and sizes, making it a popular choice for products that require complex shapes or intricate designs. It is also able to be produced in a range of colors, which further increases its flexibility.

Here are some more benefits of PET bottles.

Drawbacks of Polyethylene Terephthalate Plastic

Despite its many advantages, PET plastic does have some drawbacks. One of the main concerns associated with PET plastic is its impact on the environment. PET plastic is not biodegradable, meaning that it can persist in the environment for hundreds of years if not properly disposed of. It can also contribute to pollution if it is not properly recycled.

In recent years, efforts have been made to reduce the impact of PET plastic on the environment. Many companies have started using recycled PET (rPET) in their products, which is created by breaking down used PET plastic and reprocessing it into new products. This helps to reduce the amount of waste generated by PET plastic and reduces the need for new materials to be produced. Sailor Plastic Bottles has launched a new line of bottles using recycled PET plastic and will be stocking them as standard item.

Products from Sailor Plastics containing PET Plastic

- All products with PET Plastic

- Clear PET Honey Bear Style Bottle (8 oz, 12 oz, 16 oz, 32 oz)

- Square Clear PET Bottles with Multiple Neck Finishes & Sizes

- Round Clear PET Bottles with Multiple Neck Finishes & Sizes

- Oval Clear PET Jars & Bottles with Multiple Neck Finishes (1lb & 2lb)

Recycling Information

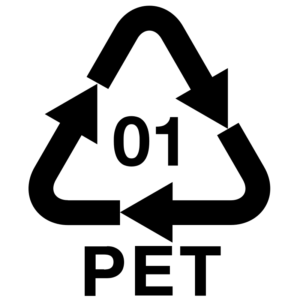

Reusability is a big topic in today's world. One of the significant advantages of PET plastic is that it is highly recyclable. PET can be melted down and reformed into new products repeatedly, making it a popular choice for manufacturers and consumers who want to reduce their environmental impact. Recycling PET also saves energy and reduces the amount of waste in landfills. However, it is important to note that not all PET products are created equal, and some may be more difficult to recycle than others. For example, products with mixed materials, such as plastic-lined paper cups, may not be suitable for recycling. Nevertheless, overall, the recyclability of PET plastic makes it a sustainable option for a variety of applications. Look for the recycling code #01 to be sure your item is made of PET.

Recycling Code #1

Safety and Regulatory Details

The regulatory details of PET plastic vary by country and region, but in general, PET is subject to regulations regarding its production, use, and disposal. For example, in the United States, PET production facilities must comply with regulations set by the Environmental Protection Agency (EPA) regarding air emissions, water discharge, and waste management. Additionally, the Food and Drug Administration (FDA) regulates the use of PET in food packaging to ensure that it is safe for human consumption. In terms of disposal, many countries have implemented recycling programs to reduce the amount of PET that ends up in landfills or the environment. Overall, the regulatory details of PET plastic aim to promote its safe and sustainable use throughout its lifecycle.

Check out our article "IS PET SAFE FOR FOOD AND BEVERAGE?" for more information regarding safety and PET plastic.

Let us help you find your ideal packaging solution

At Sailor Plastic Bottles, we truly want you & your business to succeed. And while we manufacture a wide assortment of plastic bottles, we know that sometimes you don’t know what type of bottle is best for your product. If that’s the case, give us a call. We have a ton of experience matching products to the right packaging container.

We’re proud to provide businesses in the food and beverage industry with high quality plastic packaging solutions. Whether honey bear, square, round, or oval shaped plastic bottles, Sailor Plastic Bottles has you covered. And we always deliver what we promise.