High Pressure Processing & Its Advantages

Processing fresh foods, and juices particularly, can be a bit of a conundrum. While it is important to maintain the texture, taste, and nutritional value of fresh juice, it is also important that harmful bacteria are removed, and the shelf life of the product is lengthened. This is especially true for juicers who wish to sell bottled juice as well as freshly pressed juice. High Pressure Processing (HPP) allows for both issues to be resolved. Juices that are processed using HPP are more likely to keep their fresh taste and nutritional value with a longer shelf life.

What is High Pressure Processing?

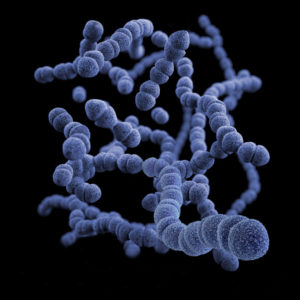

High Pressure Processing is a food processing technique that uses water pressure, rather than heat to pasteurize a wide variety of consumables. The juice industry has benefited from this technique as it offers several advantages. HPP is a cold pasteurization process which means the food does not have to reach high temperatures to remove harmful bacteria. Normal pasteurization methods can also remove healthy bacteria, which would lower the nutritional value of fresh juices. The removal of nutrients and antioxidants not only lowers the value of fresh juice, but it can also alter the taste of the juice and can make the experience of drinking it less enjoyable.

How does HPP Work?

Just like many types of bacteria cannot withstand the high temperatures of thermal pasteurization, they also cannot survive high pressure levels. Using pressurized cold water, HPP subjects already packaged products to pressure levels up to 87,000 psi. This level of pressure is higher than the lowest point of the Marianas Trench.

This process kills the bacteria, but also reduces the possibility of outside contamination, as the product is fully packaged before the process begins. This means that the integrity of the product, the texture, color, taste, and nutritional value are preserved up until the initial opening of the product. This process is popular in the juice industry, but it also useful for dairy products, dips, and deli meats.

This process kills the bacteria, but also reduces the possibility of outside contamination, as the product is fully packaged before the process begins. This means that the integrity of the product, the texture, color, taste, and nutritional value are preserved up until the initial opening of the product. This process is popular in the juice industry, but it also useful for dairy products, dips, and deli meats.

It is important to remember that any type of packaging used for HPP pasteurization needs to be durable and flexible. While the ability to withstand high temperatures is not an issue with HPP, the packaging you use needs to be able to stand a large amount of pressure. It needs to be durable, so it doesn’t break during the process, but flexible enough to retain its shape after the process is over. Plastic manufacturers, like Sailor Plastic Bottles, often make HPP compatible bottles for juices, dressings, and sauces that would benefit from HPP pasteurization. These bottles are made specifically to handle the high-pressure environments created by HPP and are often a great choice.

If you are interested in starting a fresh food-based business, knowing the basics of High-Pressure Processing (HPP) can help you learn which pasteurization process is the best choice for you. HPP uses high amounts of cold-water pressure to destroy bacteria while keeping the taste and texture of foods intact. It is a great alternative to traditional thermal methods that works wonderfully for fresh foods.

About the Author:

Jessica Welch is a student at Minnesota State University- Mankato who is working towards an MFA in creative writing. She has helped work on business related blogs and product descriptions as an intern with Sailor Plastic Bottles.